eCUT de-risks at small scale and deploys at large.

Efficiency

≫ Selective electrochemical process for high yield of desired product

≫ Expands plant capacity with no incremental fossil fuel feedstocks

≫ Low energy and low pressure process

ease of integration

≫ Modular implementation

≫ Scalable to meet demand

≫ Easily integrable to current monomer production processes

≫ Products can be produced where utilized

Product Features

≫ Produces high performance, industry grade monomers

≫ Carbon negative process

≫ Low cost solution for carbon emissions

How does Ecut work?

Carbon dioxide enters the electrolyzer along with water, and the reactor is powered by electricity.

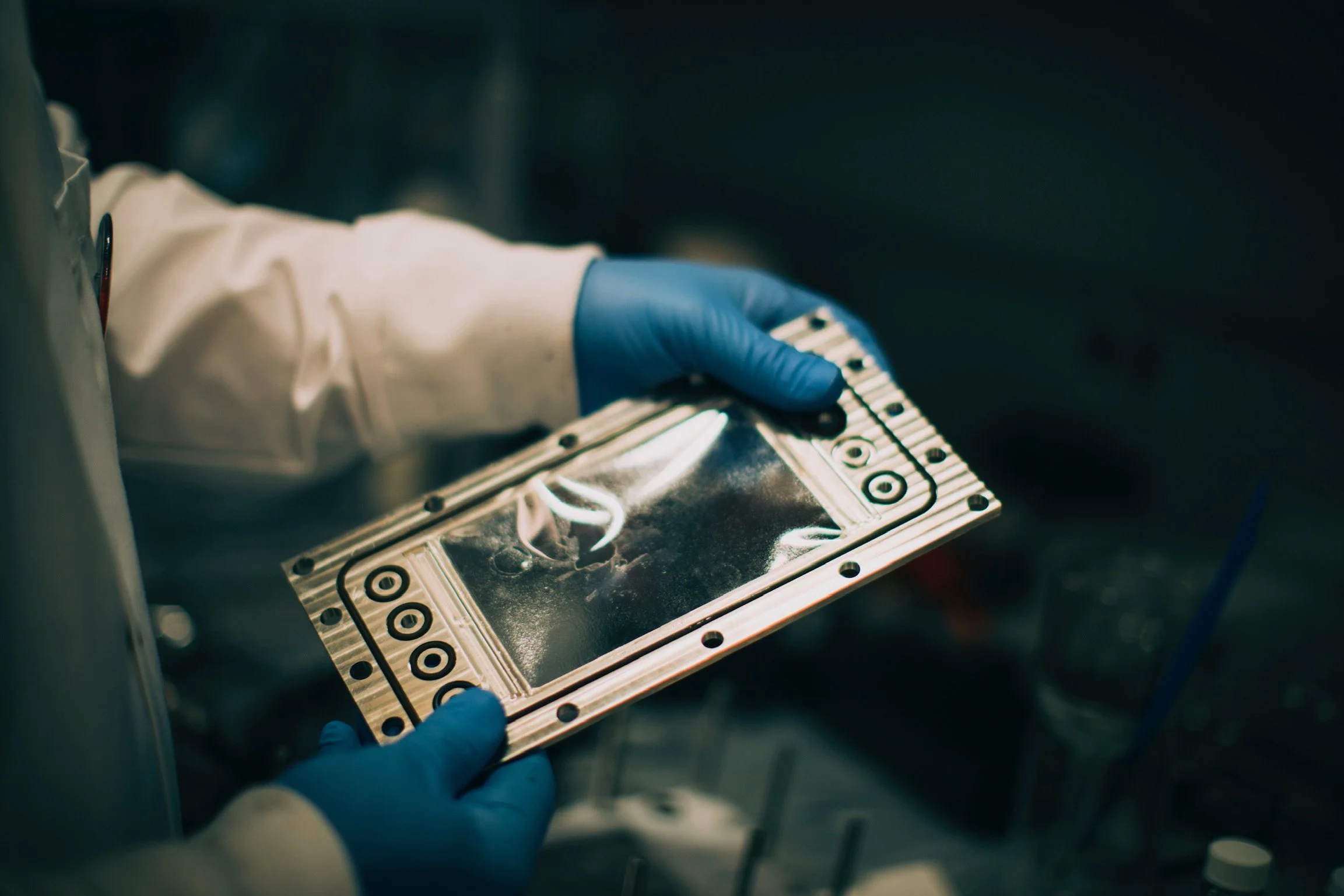

At the cathode inside the electrolyzer, carbon dioxide is reduced to an organic compound, like methylglyoxal (MG). Our patented catalyst accelerates this reaction with less energy and ensures high selectivity for the desired product.

At the anode, water is converted to oxygen.

The membrane between the electrodes facilitates ion transport in an optimal process.